Run Capacitor vs. Start Capacitor: What’s the Difference?

If you’ve ever encountered a home appliance malfunction of any kind, you know that it can be incredibly frustrating. The complicated assembly of parts that make up just about anything electrical can often leave even experienced repair professionals baffled at times. However, in diagnosing many of these problems you may come across components you’ve never heard of such as run capacitors and start capacitors. The two might seem basically interchangeable at first glance, but there are actually significant differences between these two important parts. Knowing these distinctions will help you make a more informed decision when it comes to repair or replacement of your faulty appliance.

Overview

A run capacitor is an electrical component found in a variety of motor-operated equipment, such as air conditioning systems, dishwashers and refrigerators. It’s designed to store and discharge electrical energy to improve the performance of the motor by creating a pulsing magnetic field in order to increase the supply of current flowing to the motor. A start capacitor, on the other hand, is designed to remain totally discharged over time. Whereas the run capacitor works in tandem with the motor to continually supply electrical power, a start capacitor is designed to aid in providing just that – a starting burst of electricity in order to ensure the motor has enough power to run at an optimal level.

Characteristics

Run capacitors and start capacitors differ in a variety of ways. For instance, a run capacitor is able to store electrical energy for extended periods of time and is made up of several layers of plastic and aluminum foil. This electrical component typically has two metal terminals and is described as a cylindrical object. Start capacitors, however, only store electrical energy for a brief period of time and are cylindrical in shape andhave three metal terminals. More specifically, a run capacitor retains its size during use, while a start capacitor can expand and contract repeatedly.

Durability

The differences between run capacitors and start capacitors can also be seen in terms of their individual lifespans and resilience. Generally, run capacitors are constructed to run non-stop, ensuring that they are designed to last much longer than start capacitors. On the other hand, start capacitors have a shorter lifespan of 1-3 years due to the amount of stress they are put through each time they are fully energized.

Benefits

The primary benefit of the use of a run capacitor is the increased amount of torque supplied to the motor. This makes it easier for the motor to start and maintain a constant speed, which helps reduce the amount of electrical current to the motor. This, in turn, improves the efficiency of the motor and helps to control the amount of electricity being used in the home. Additionally, because run capacitors stay energized almost continuously, they often tend to have a longer lifespan than start capacitors, offering a cheaper long-term option for specialized motors.

By contrast, start capacitors offer quick bursts of energy and the increased torque required to start a motor quickly. In other words, they are an important component in providing the initial power required to get the motor up and running. This helps to reduce the amount of energy required to get the motor running, saving the homeowner on their energy bill. What’s more, in the event of a power outage, start capacitors will often jumpstart the motor once power is restored, ensuring that you won’t need a service technician to physically start the motor.

When To Use

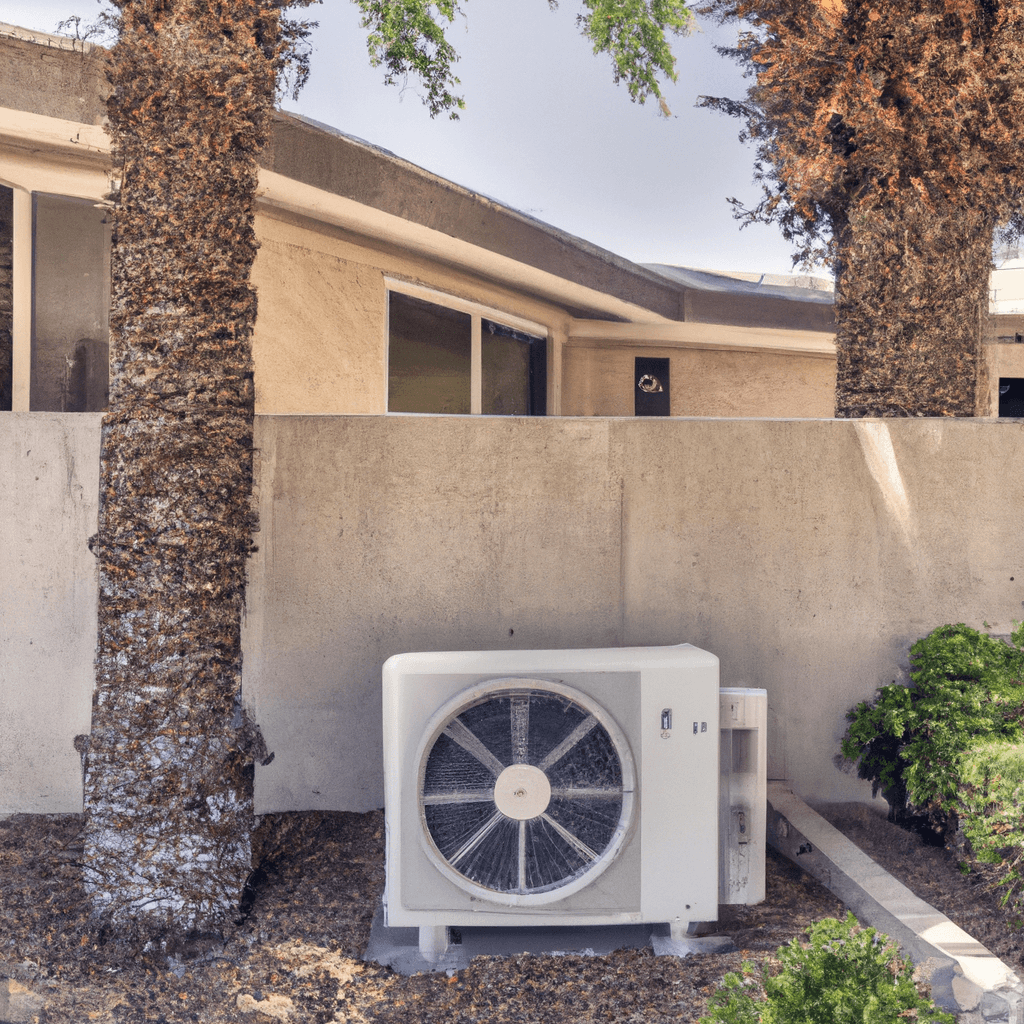

Run capacitors are best utilized for motors that require continuous use, such as in HVAC systems, water pumps and powering conveyor belts. Start capacitors, however, are best reserved for motors that don’t need to run continuously, such as air compressors, fans and blowers.

Why Local Reliable Appliance Repair?

No matter what kind of appliance repair project you find yourself tinkering with, there are certain projects that require a trained and certified repair professional with specialized tools and experience. If you find yourself in need of appliance repair help, it’s important that you call a local, reliable appliance repair professional like Local Reliable Appliance Repair. With their years of experience they can tackle the challenges of appliance repair, ensuring that your appliance is fixed correctly and safely the first time. Plus, their efficient and professional services ensures that your repair will be finished in no time. To schedule an appointment, give them a call at (866) 311-8590.

Run Capacitor vs. Start Capacitor: Best Practices for Installation

When installing and replacing components in an air conditioning and heating system, there are several types that must be identified and harnessed together. One of the most common issues associated with air conditioning and heating systems are Run Capacitor vs. Start Capacitor problems. To help ensure that the appliance or HVAC system is running correctly, preventive actions must be taken to avoid such issues and any potential problems associated with them. Here are a few recommendations from manufacturers, local appliance companies, and HVAC technicians to help guide you through the process.

Understand the Difference

Before any work is done, it is important to understand the difference between run capacitors and start capacitors. A run capacitor is a component used to help the motor run more efficiently and help save energy, while a start capacitor is used to help the motor reach its maximum torque. When both components are properly sized and installed, they allow the motor to start and run smoothly, thus avoiding any potential problems.

Proper Sizing

The most common problem associated with run and start capacitors is improper sizing. If the run capacitor is too big, it will cause the motor to run too fast and if the start capacitor is too small, it will not offer the necessary torque to get the motor going. Proper sizing, measured in either frequency or voltage, of both capacitors can help ensure a safe and effective installation. An appliance specialist or HVAC technician can help you determine the correct size for your specific system.

Corrosion Prevention

Corrosion is a common issue associated with all types of electrical components, and air conditioning and heating systems are no exception. To help prevent such problems, it is important to use special compounds specifically designed to resist corrosion when installing the components. Many of these compounds also come with thermal protection in case of overheating.

Double-Check Connections

Ensure that all connections are secured properly by double-checking them with a multimeter or voltmeter. In addition to that, make sure that the wiring is not exposed and properly insulated. Even a small exposed wire can cause dangerous electrical shock.

Use Quality Components

When installing and replacing components in an air conditioning and heating system, quality should be a priority. It is important to use components produced by a trusted manufacturer in order to avoid any potential problems. Poorly made capacitors could cause performance issues, as well as cause damage to the motor and other components.

Last Check

Finally, once the components are in place and the connections are properly secured, it is important to perform a final check. This can be done using a voltmeter or tester to make sure that the voltage and current levels are accurate and that the capacitors are compatible with the system.

Following these recommendations from manufacturers, local appliance companies and HVAC technicians can help ensure that the air conditioning and heating system is functioning smoothly and safely. If you need help with a Run Capacitor vs. Start Capacitor issue, please call Local Reliable Air Conditioning & Heating at (866) 311-8590.

Average Repair Cost for Run Capacitor vs. Start Capacitor Issue

Repair or installation cost for a run capacitor versus a start capacitor issue vary greatly. On average, a simple repair or installation might cost around 20% more than before. Typically in California, a complex repair or installation could cost up to double of a simple fix.

Every repair job is different and parts necessary depend largely on the specific circumstance. However, most issues involve replacing connectors, terminal screws, run or start capacitors and other miscellaneous hardware. Here is a general idea of what you can expect in terms of cost and parts necessary:

- Connectors & Terminals: $45 – $100

- Run & Start Capacitors: $25 – $100

- Miscellaneous Hardware: $5 – $20

Additional cost may include material and it typically ranges from $10 – $25. If a technician determines any major components (such as an HVAC unit) need replacing, then the cost can increase significantly. It is always a good idea to contact a local, reliable air conditioning and heating service for an exact estimate.

For best results, call Local Reliable Air Conditioning & Heating at (866) 311-8590. Their team will be able to provide you with the right information and solution for your specific situation. They are known for fast response times, excellent customer service and competitive prices.

Run Capacitor vs. Start Capacitor: The Pros and Cons

The debate over the use of Run Capacitor vs. Start Capacitor has been a long one. While both can help prolong the life of your air conditioning system, each has its own advantages and disadvantages.

A start capacitor is an electrical capacitor that is typically used to temporarily increase the power output of an appliance. It is used mainly with air conditioning systems, and works by temporarily increasing the auxiliary torque produced by the motor. This temporary boost lasts until the start capacitor is disconnected by the capacitor’s timer switch.

On the other hand, a run capacitor is an electrical capacitor that is typically used to permanently maintain a continuous power output of an appliance. It is used mainly with air conditioning systems, and works by maintaining the electrical current which allows the motor to run at a more reliable and consistent speed.

When it comes to air conditioning system, Reliable Air Conditioning & Heating is the best choice. Our family-owned California business offers same-day service for appliance and HVAC repair and installations. Our highly-trained technicians have a minimum of 5 years of field experience. We always use quality parts and offer fair and affordable pricing. We are licensed and insured and offer a 90-day warranty on any repairs we make.

When it comes to deciding whether to use a start capacitor or a run capacitor, consider the help of Reliable Air Conditioning & Heating. We provide only the best service and quality parts to ensure your air conditioning system runs into peak performance. Contact us today for assistance with your air conditioning system, and trust the professionals at Reliable Air Conditioning & Heating for all your appliance and HVAC needs.

FAQ – Run Capacitor Vs. Start Capacitor

What is the difference between a Run Capacitor and a Start Capacitor?

A run capacitor is an electrical device used to increase the efficiency of an electric motor, such as an air conditioner’s compressor motor. They keep the current and voltage within specific limits, allowing the motor to run more efficiently and at a cooler temperature. A start capacitor temporarily increases the motor’s starting torque and allows it to be cycled on and off rapidly.

Why is it important to know the difference between a Run Capacitor and a Start Capacitor?

It’s important to understand the distinction between run and start capacitors because if the wrong one is used it may lead to a malfunctioning system, potential damage to the air conditioner’s compressor motor, or even an electrical fire. Replacing the wrong capacitor with the correct type is important.

Are there differences in maintenance between Run Capacitors and Start Capacitors?

Run capacitors are designed to last the life of an electric motor or appliance, whereas start capacitors have a limited operating lifespan. The lifespan of a start capacitor can be affected by excessive heat, age, and electrical ripple current, and generally should be replaced every few years.

What might be a sign that a Start or Run capacitor needs to be replaced?

A common sign that a start or run capacitor needs to be replaced is an excessive humming or buzzing sound coming from the motor. Additionally, the air conditioner’s airflow heating or cooling may be weak or erratic. If you suspect an issue with your motor’s capacitor, it’s recommended to call a local, reliable appliance repair technician.

For any questions regarding Run Capacitor vs. Start Capacitor, call Local Reliable Appliance Repair at (866) 311-8590.